Welding & Fabrication

We offer a comprehensive range of welding and fabrication services, including work on mild steel, stainless steel, zintech and aluminium.

Steel Welding

We offer high quality steel welding, suitable for a range of projects such as tables, jig work, stillages, cages, lifting equipment and gates.

Aluminium Welding

Skilled aluminium welding suitable for catering equipment such as chip pans, gates and railings, HVAC equipment and more.

On-Site Welding

We can assist with large-scale projects on site to deliver quality installations with our portable welders and generators.

Our Services

Turning individual tubular or pressed components into welded assemblies using metal arc welding equipment, linishing and polishing machinery and more to finish products to a high standard.

Processes

- Cutting

- Drilling

- Folding

- Welding

- Finish work

- Painting & powercoating

Welding & fabrication in Birmingham

Midland Fabrication specialise in the design and manufacture of mild steel, stainless steel and aluminium parts. Our work is fabricated in our workshop in Birmingham to ensure a smooth process from enquiry to completion. We cater to all sectors, on residential apartment buildings, industrial units and commercial office buildings.

Design

We can work from existing drawings, or we can create CAD drawings and 3D renders to ensure the efficient fabrication of your parts. We also offer site surveys for accurate quotations.

Manufacturing

We are proficient in MIG & TIG welding and can work with mild steel, stainless steel and aluminium.

Quality

We take pride in our work, no matter the project size. We can assist with large-scale projects on site, or can create prototypes and finished products in our Birmingham workshop.

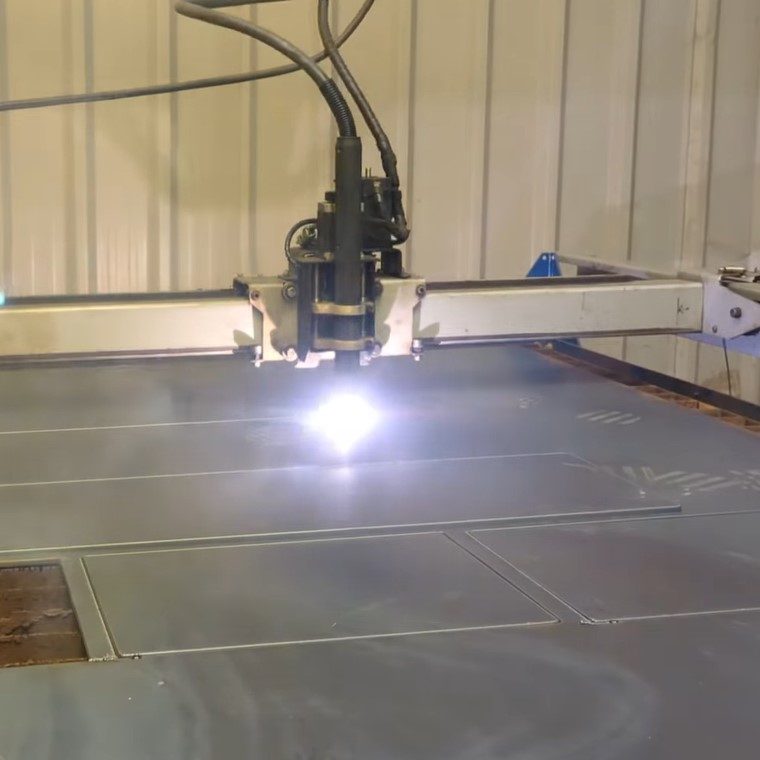

Up to 25mm plasma cutting in Birmingham

Our in-house plasma table easily profiles mild steel sheets up to 12mm thick.

In this project, it glided through this 5mm mild steel easily.

Our Hypertherm Powermax 65 Sync allows us to profile plates up to 25mm in thickness.

Contact midlandfabricationltd@gmail.com for a quote on your metal cutting requirements.

Steel light fittings for engineering company

Take a look at these darts-themed light fittings, fabricated for a local engineering company in Birmingham.

TIG welding can offer a low profile solution to joining metal together which offers a far superior finish for decorative products.

Our customer has some more work to do to these before you might be able to see them in your local pub!

Mild steel parts for manufacturing facility

Mild steel sheet metal fabrication for a manufacturing facility.

We designed and created a prototype for this part, before cutting it on our own plasma cutter, folding it, welding it, finishing it, and finally painting it.

Contact midlandfabricationltd@gmail.com today to take advantage of our full process manufacturing offered in the midlands.

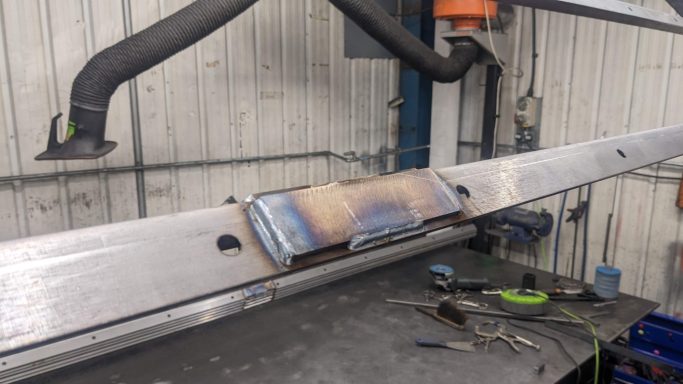

Heavy-duty aluminium MIG welding

Aluminium MIG welding on some heavy duty gantry brackets.

MIG welding aluminium provides a quicker turn around time than TIG welding reducing the cost of manufacturing on long production runs.

Get in touch today to see what Midland Fabrication can do for you.

Contact us

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.